First stop on the Bourbon Trail, was Makers Mark distillery. They bottle 9000 cases a day. Below is a picture of the distillery when it was founded in 1953. Above is the house of the original founders in the background.

The trademark on Makers Mark bottles is a star with an S IV. The star stands for the name of the farm that the founders owned near Bardstown. The S IV is for 4th generation of Samuels that run the distillery.

Below is where they cook the mash (grains with yeast and distilled water). Bourbon can be made anywhere in the US, but the limestone in this area of Kentucky filters the iron out of the water, which makes it superb for distilling whiskey. Above are the copper kettles used in the distilling process. Bourbon is distilled twice for purity.

A few of the many bourbons bottled by Makers Mark.

The labels are all made right here in their facilities. This operator can make 63,000 labels a day.

Makers 46 is one of their more popular labels. 46 stands for the recipe number that was decided on when the company was creating a new bourbon. There are 4 requirements in order for a whiskey to be called a bourbon. 1. It must be aged at least 2 years. 2. It must be aged in a new white oak barrel. 3. It must be at least 51% corn. 4. It must be made in the USA.

The first distilleries in this area were started in the early 1800's. Most of the whiskey was put in barrels and shipped to New Orleans, where it was shipped all over the world. One distillery accidentally caught on fire and the barrels were charred. Instead of making new barrels to ship the whiskey in, he went ahead and shipped the whiskey in the charred barrels. When the whiskey got to New Orleans, those who bought it immediately fell in love with the amber colored whiskey. The art of charring the interior of the barrels before aging the whiskey was born. The coopers who make the barrels for the distilleries have many different ways of charring the interior of the barrels. So Makers decided on recipe #46 for their new bourbon.

Below is the building where they bottle 9000 cases a day. They take 150 barrels from different warehouses and blend them before bottling.

Empty bottles being filled above. All the necks are hand dipped in the signature red wax.

Filling the cases above. The entire line from start to finish below.

The truck is full and ready to be shipped.

On to the tasting room. The one on the left is called Makers White. It is only aged a short time. Makers 46 is on the right. It's aged for 7 years.

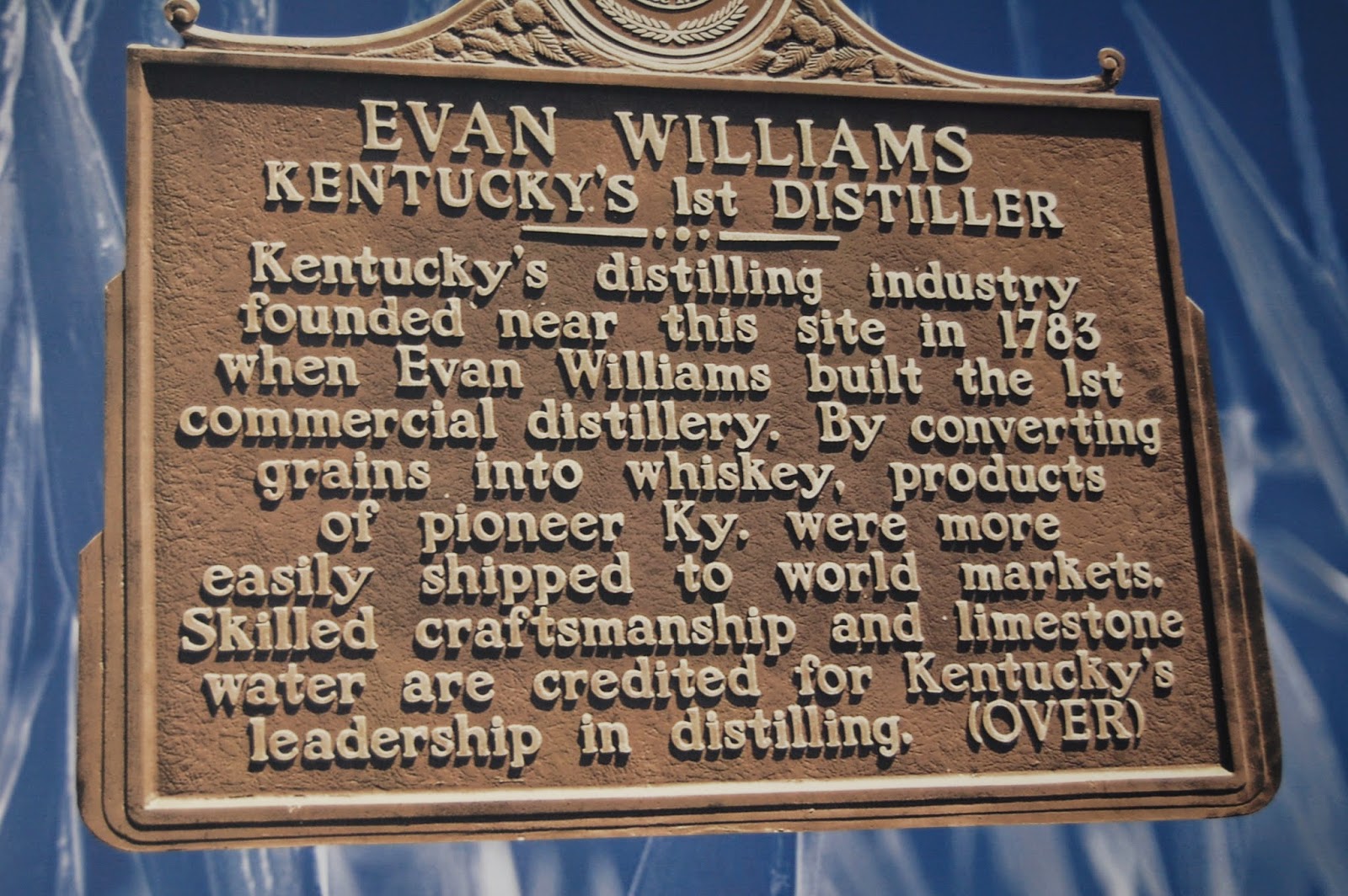

On to Heaven Hills distillery. There signature bourbons are Evan Williams and Elijah Craig. Heaven Hill's Master Distiller is a descendant of Jim Beam. Above just a few of the 44 aging rick houses that hold thousands of barrels.

Below is a sample of the charred slates they use in the interior of the barrels. The slates vary a great deal in the degree that they are charred and what is used to char them.

In the 4 corners of each building are hanging plum bob's indicating how level the building is. When they load or unload barrels, they have to be careful that the same amounts are taken from different sides of the building. Otherwise the whole building could collapse.

Beautiful tasting room at Heaven Hill. I'm starting to like this bourbon.

Above is a very small distillery called Willett. It's called a craft distiller which is the name given for these small operations. Below is the distilling kettle used to distill all of their bourbons. A picture of this Aladdin type distiller is used on their labels.

So we made it to 3 of the distilleries. Several more to go between Bardstown and Lexington. Guess it will have to be another trip.

No comments:

Post a Comment